H/T section steel assembly welding turn over correction one-time forming

Parameter:

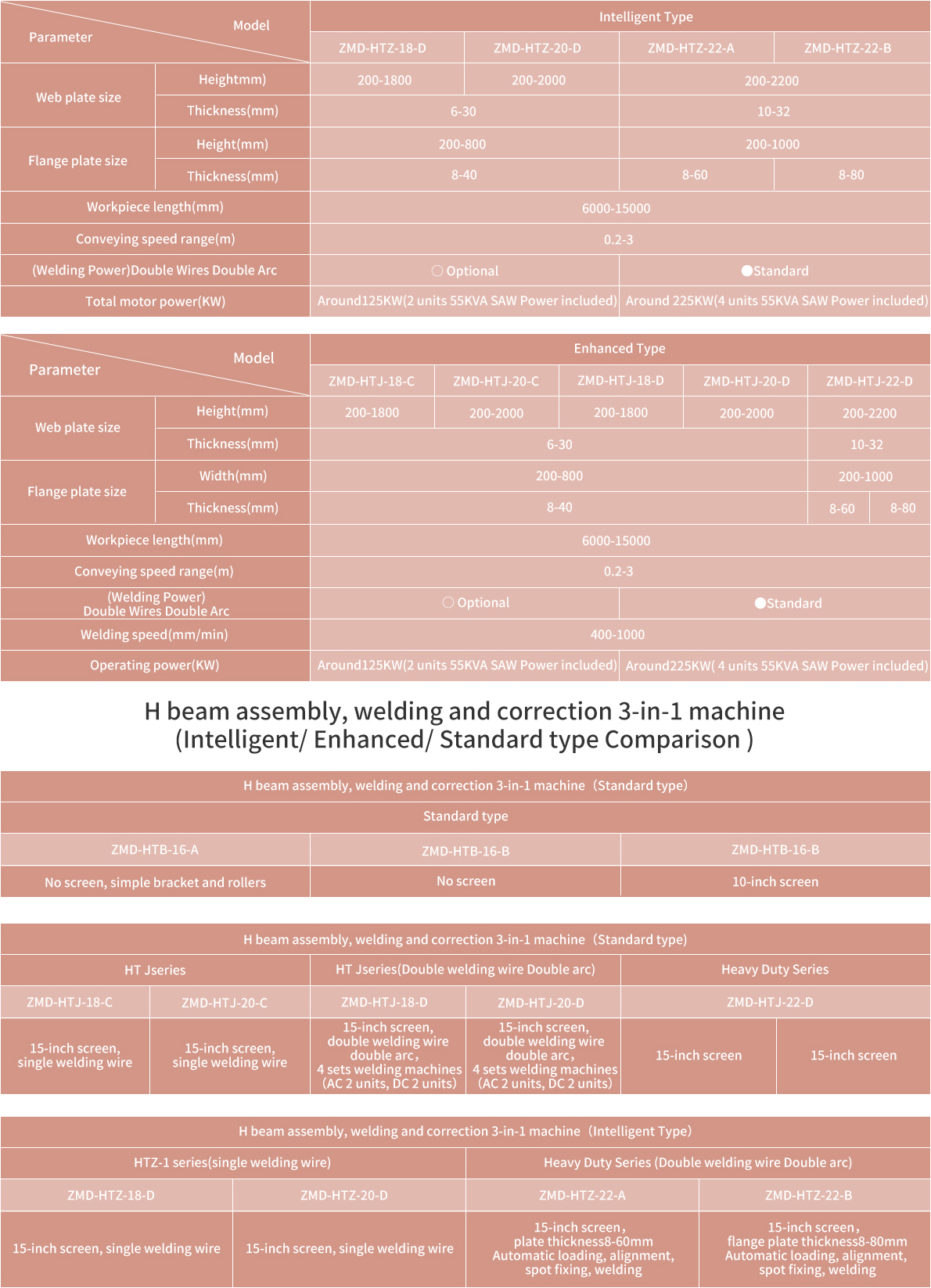

Web plate Height:200mm-2200mm Web plate Thickness:10mm-32mm

Flange Plate width:200mm-1000mm Flange Plate Thickness:8mm-80mm

Thickness:6000mm-15000mm

Applicable industry:

Prefabricated construction,bridge engineering,shipyard,etc

1,Cost saving,high cost-performance

①Save debugging cost ;

②Save labor cost ;

③Reduce the risk of work injuries;

④Reduce equipment purchase cost (1 equipment =3 equipments);

⑤Reduce the cost of space;

⑥ Save the cost of consumables ,compared with the traditional equipment,hoisting machinery input reduced 3 sets;

⑦Low cost,high return.

2,Higher production efficiency

① Compared with the traditional equipment,,the web plate less than 18mm free from groove welding,according to the thickness of the plate,the ideal welding speed can be up to 1m/min;

②Adopting hot straightening method for one correction,reduce the operation procedure,no spot welding in assembly process,no arc-leading plate required,standardized operations,products qualified rate high;

③Workpiece travel during the operation while the equipment fixed,equipment continuous work,workpiece uninterrupted welding,efficiency increases.

3,Advanced technology

①Invented patented products,and reached the international advanced level;

②T-shaped steel single welding forming;

③Have got the invention patents of hot welding and hot straightening process and no groove submerged arc welding technology.

④According to the thickness of the plate can intelligently match the corresponding welding current,voltage and other parameters,suitable for a variety of complex welding conditions.

4,Simplify Operation

①The intelligent type/enhanced type of the all-in-one is equipped with a 15-inch touch screen,the operation panel is clear,1 person can control operation;

②Simple structure,easy maintenance,local use of maintenance-free graphite structure,also can upgrade automatic maintenance lubrication system.

5,Wide application range

①Intelligent type/enhanced type of the all-in-one machine can process a wide range of workpiece,Web plate height 200-2200mm,web plate thickness 6-32mm,Flange Plate width 200-1000mm,Flange Plate Thickness 8-80mm;

②It can be used in more than 20 industries such as prefabricated construction and bridge engineering.

6,Strong stability

① The core parts of the intelligent type/reinforced type of the all-in-one machine are cast parts,which are better than steel plate splicing or welding parts to effectively ensure the service life of the equipment;

②Precision machining roller table,fast transmission process,can effectively prevent welding jitter;

③More than 15 years of research and development experience,Cumulative sales of more than 10,000 units of equipment,Mature technology and low failure rate;

④Each process structure adopts parallel finite element analysis and design,precise calculation,breaking through the world-class problem of welding anti-deformation.

7,Intelligent production

Intelligent type of all-in-one machine is equipped with intelligent flange plate clamping device,intelligent plate feeding and righting device,intelligent towing system,intelligent fixation system,intelligent detection system,intelligent flux feeding system,intelligent correction system,intelligent lifting device,higher production efficiency.

8,Service quality is guaranteed

①Reserve system upgrade ports to reduce later equipment update costs;

②Lifelong training to avoid personnel changes affecting product production;

③To provide quality assurance services,with a service team of 100 people,for stable production escort.

The video display content is for reference only. Please refer to the physical/technical agreement for details.