1.The "Jueying" six-pole three-arc welding machine features high speed and efficiency

①Compared with traditional welding machines,Zhimaide "Jueying" six-pole three-arc welding machine achieves fully automated welding,eliminating the need for beveling under 18mm,which can significantly enhance production efficiency and product quality for manufacturing enterprises.

② Zhimade "Jueying" six-pole power supply set enables three arcs to weld simultaneously,which can generate a welding area with a higher temperature in a short time.The welding speed is 3 to 5 times that of traditional welding machines.

③Equipped with an adaptive thrust current regulation function and an automatic arc voltage regulation (variable speed wire feeding) system, it features high speed,high control accuracy,and further enhanced welding efficiency.

④The current is strong,the arc is stable,the arc starts quickly,and it can be welded all the way without interruption,saving time and effort.

⑤It meets the requirement of wider weld gap,and the connection after welding is tighter and more firm,ensuring the welding quality.

2."Wuzhui" six-pole six-arc welding machine,thick plate formed at one time

①Zhimaide "Wuzhui" six-pole six-arc welding machine,matching carbon steel deep penetration K-TIG welding technology,six electrodes,six arcs heat output high and concentrated,strong penetrating power,when welding sheet metal,it can achieve beveling without groove welding less than 25mm web.

②The front gun adopts the DC flat characteristic and the rear gun adopts the DC pulse mode,which not only ensures the penetration depth but also takes into account the formation of the cover surface,reduces heat injection,avoids the damage of thermal effects to the sheet,and effectively solves the technical problem of one-time forming automation in thick plate welding.

③The arc starts smoothly,the arc is stable,effectively achieving stable welding surface formation,the weld seam is beautiful,the deformation is small,and the component qualification rate is high.

④Solid core welding wire,automatic wire feeding,fully exploits the advantages of submerged arc welding such as high current and high deposition rate,improving welding efficiency and weld quality;

⑤According to the hardness of the steel,high-performance flux is selected.The arc is stable,the weld formation is good,the slag removal is fast,and less welding smoke is generated during the welding process.

3.Smart Internet of Things, easy to operate

①The 15-inch touch screen displays real-time welding data,allowing for an intuitive understanding of the equipment's working status and making operation more convenient.

②The welding current and voltage can be independently adjusted.It is equipped with multiple process parameter templates that users can edit and modify.

③The working states of the front and rear welding torches can be controlled separately to be compatible with conventional welding machines.

④Zhimade Smart Internet of Things system can be selected to automatically calculate the usage of welding wire and flux, accurately calculate the welding output, and conduct remote control, ensuring stable production.

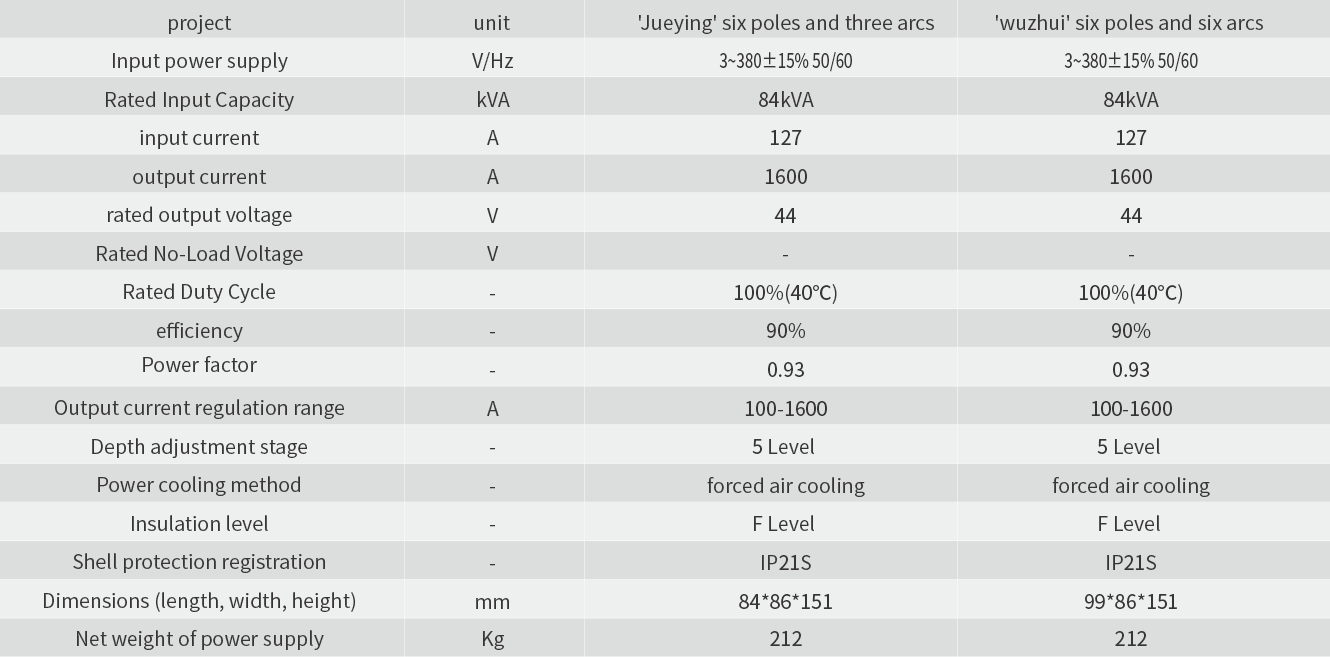

⑤The welding power supply features high efficiency,large power,low no-load loss,and is more energy-efficient.It is equipped with overvoltage,undervoltage,phase loss,and overheat protection functions.

⑥Compact in structure, small in size, light in weight and more flexible in use.

4.Widely applied and reliable in quality

①With ten years of experience in the research and development and production of steel structure equipment,Zhimaide is a source factory with a complete quality system and guaranteed products.

②All components are from well-known domestic brand suppliers. The whole machine is well-matched and has stable performance.

③It has a wide range of applications and has been used in fields such as steel structure processing,aerospace,locomotives,ships,petrochemicals,substations, and automobiles.

④One-time purchase, lifetime warranty.Professional after-sales personnel will guide installation and use,ensuring reliable after-sales service.