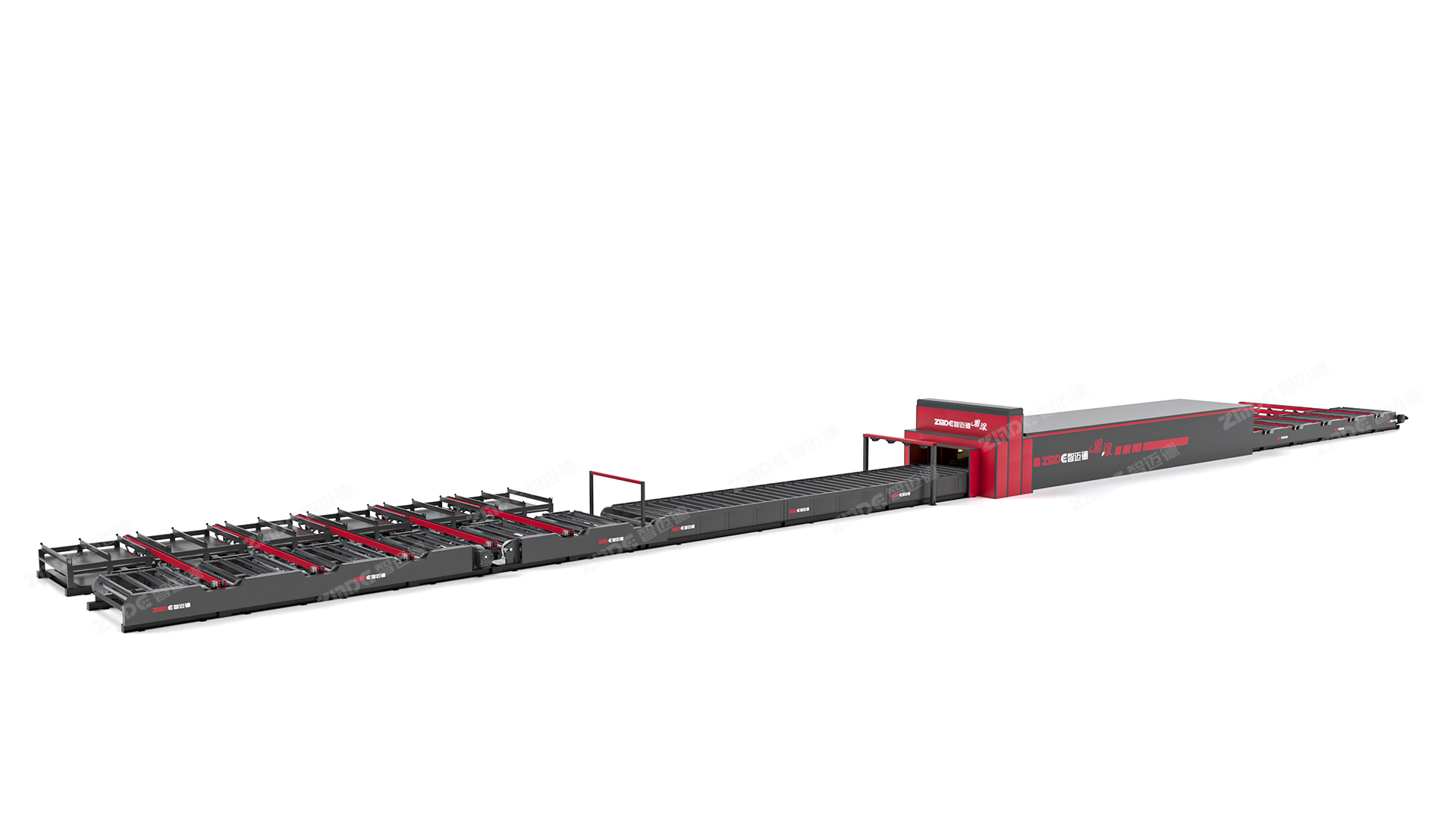

Zhimaide Yatu Coating Steel Structure Intelligent Spraying Production Line is a high-tech and automated device specifically designed for the spray painting treatment on the surface of steel components.This production line system resolves the problems existing in manual spraying,such as high labor intensity,poor environment,low efficiency,high labor and material costs,and unstable coating quality.It has the advantages of requiring fewer workers,low labor intensity,high spraying efficiency,good spraying quality,uniform coating and paint saving.It has achieved "saving,intelligence,speed,efficiency,cleanliness,smoothness and safety", and is a new equipment for more efficient and intelligent spray painting operations in steel structure processing enterprises.

Core parameters:

Minimum visible vertical board: ≥6mm

The minimum angular resolution of the sensor is 0.1667 degrees

Maximum scanning range: 190 degrees

Spraying ambient temperature: -30 to 50℃

Spraying speed: 1.3m/min(within a width range of 3m)

Lifting height: 500mm

Single load-bearing capacity: 3.5 tons

1.Save-Save a large amount of labor

The central control system ensures full automation throughout the process,requiring only three general workers.This saves working hours,is highly efficient,and reduces occupational health risks.

2.Intelligence-Intelligent Recognition component

3D scanning conducts all-round identification of components,automatically builds models without programming,and effectively realizes the intelligent start and stop of spraying.

3.Fast-Rapid automatic spray painting

There are two sets of spray guns,six in each set,for all-round operation.The spray guns can switch automatically to save paint.Quickly adjust the spacing of components,reduce the waiting time for spraying,and achieve greater efficiency.

4.High-efficiency automatic drying

The radiation drying system conducts flameless combustion of natural gas,avoiding energy loss, being environmentally friendly and energy-saving.When combined with water-based paint,it dries quickly and efficiently,significantly shortening the production cycle.

5.Purification-Purify organic waste gas

The negative pressure through-type spray booth,when paired with Zhimade three-way rotor intelligent integrated machine, is specifically designed for the treatment of organic waste gas.With a volume of 10,000 cubic meters per hour,it can solve environmental protection problems at a low cost.

6.Smooth-Smooth traditional system

The longitudinal conveying adopts a chain T-shaped structure,which is highly stable,and the spraying is unobstructed,reducing the need for touch-up paint.The lateral conveying lifting device adopts a scissor design,which is safe,stable and efficient.

7.Safety-Safe operation,customer peace of mind

Zhimade has accumulated ten years of experience in equipment manufacturing,uses solid materials and has undergone strict quality tests.Equipped with safety detection devices to ensure the safety of staff and the peace of mind of customers.