Zhimaide Product Advantages

Product introduction

Submerged arc welding wire is a type of welding materials, commonly used for carbon steel welding. Submerged arc welding is a special welding method.With higher welding quality and stable, generally used in workpieces with high welding requirements.

Product advantages: Submerged arc welding wire has excellent weldability and mechanical properties, stable arc, easy slag removal, good weld formation, and high deposition efficiency.

Product use

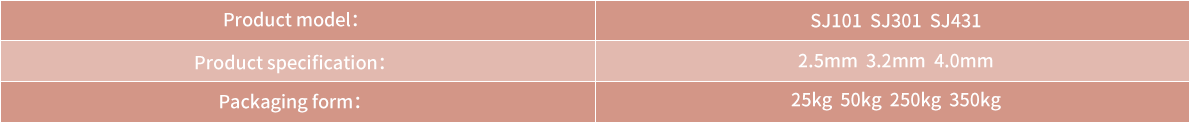

The submerged arc flux can be used for high-speed welding and filler welding with SJ101, SJ301 and SJ431 sintered fluxes, and base metals of Q235, Q345, Q355 tensile strength grades,suitable for prefabricated buildings, steel structures, pressure vessels, heavy machinery, large diameter oil and gas water pipes, transport machinery, ships and other longitudinal circular seams,and welding at positions such as large thickness grooves.

Matters needing attention

1,Welding line energy will directly affect the mechanical properties of the weld metal. Before use,the process should be evaluated according to its own welding conditions, and formulate appropriate process specifications.

2. Need to remove rust, oil, water and other impurities on the welding surface before welding, the welding wire should also be clean and free of oil, rust and water before use.

3. The flux needs to be baked for 1-2 hours before use (sintered flux baking temperature 300-350℃, molten flux baking temperature 200-250℃).

4. Attention should be paid to the ambient temperature and humidity for storage and storage. The indoor temperature should be above 5°C, the relative humidity should not exceed 60%, certain distance (≥300mm) from the ground and walls;indoor classification storage, and a clear sign.